Mailbox:

info@hskcoltd.com

Mailbox:

info@hskcoltd.com

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Automotive stamping parts refer to components and elements in the automotive industry that are manufactured through a process called stamping. Some common examples include body panels, fenders, hoods, doors, brackets, chassis components, and structural reinforcements. Additionally, more miner parts like engine mounts, brackets, and electrical connectors are also produced through stamping.

These parts are crucial in creating structurally sound, functional, and safe automotive. They form the structural foundation of vehicles, providing the framework that ensures strength, rigidity, safety, stability, handling, and ride comfort, contributing to the car's overall performance. This article sheds light on the fundamental principles behind the material selection of automotive stamping parts.

The material selection principle for automotive stamping parts is critical to designing and manufacturing components that meet the automotive industry's stringent requirements. Let's explore the importance of each criterion in the selection:

Automotive stamping parts are often exposed to environmental conditions, including moisture, road salts, and chemicals. Sinless steel and galvanized steel are commonly chosen for their exceptional corrosion resistance, ensuring the longevity and reliability of the stamped parts.

Many automotive stamping parts, such as chassis components and structural reinforcements, are subject to significant mechanical stresses. High-strength materials, such as steel alloys, especially high-strength low-alloy (HSLA) steels, withstand these loads and maintain the vehicle's structural integrity, making them ideal choices for critical applications.

Certain automotive stamping parts may be subjected to abrasive conditions, such as contact with road surfaces or abrasive particles. Select materials with good abrasive resistance, such as hardened steel alloys, ceramic composites, or special coatings, to withstand wear and tear, prevent premature degradation, and ensure prolonged service life.

Automotive stamping parts are subjected to repeated loading and unloading, which can lead to material fatigue and failure over time. Choose materials with high fatigue resistance titanium or aluminum alloys to bring out their superior performance.

Automotive stamping parts are often exposed to temperature variations during vehicle operation. Consider materials with a low expansion coefficient volume to minimize dimensional changes and prevent warping or distortion due to temperature fluctuations.

Material is a crucial factor affecting the quality and life of automobile stamping parts. Let's explore the advantages of the most common materials used in automotive stamping parts manufacturing:

ü Low carbon steel: Excellent formability, strength, weldability, and cost-effectiveness

ü High-strength steel (HSS): Enhanced tensile strength and rigidity

ü High strength low alloy (HSLA): Combination of the advantages of high-strength steel with improved formability

ü Advanced high strength steel (AHSS): Exceptional strength, formability and lightweight, enhanced crashworthiness and fuel efficiency

ü Ultra high strength steel (UHSS): Unparalleled strength and stiffness

ü Aluminum 5000/6000: Low density, lightweight and improved fuel efficiency, a favourable strength-to-weight ratio and corrosion resistance

ü Carbon fibre reinforced plastics (CFRP): Exceptional strength and low weight

At Hashimoto Precision, we stand out for our commitment to developing and producing high-precision and small-scale automotive stamping parts. We are committed to excellence, offering a range of cutting-edge stamped components that cater to the ever-evolving demands of the automotive industry. Let’s explore some key features of our automotive stamping parts solutions that make them a preferred choice:

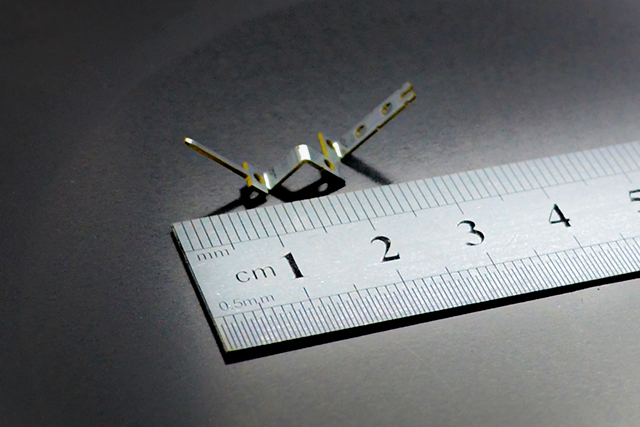

Hashimoto Precision’s automotive stamping parts are manufactured under proven technology, machines, and professional workers and on the premise of low material consumption, such as one of our featured products C2680 Wire Terminal Connector.

With decades of experience in the automotive industry, Hashimoto Precision boasts a proven manufacturing system (our products have ISO9001, ISO14001, and IATF16949 certificates) that ensures consistent and high-quality stamped components.

Our automotive stamping parts demonstrate excellent stiffness, providing optimal structural integrity and durability. They are also engineered to fit seamlessly in various automotive applications.

Recognizing the importance of weight reduction in modern vehicles, we excel in creating lightweight automotive stamping parts by utilizing materials with high strength-to-weight ratios, such as advanced high-strength steel and aluminum alloys.

In conclusion, the choice of material in automotive stamping parts manufacturing is a critical factor that directly influences vehicles' performance, safety, and efficiency. By carefully assessing the properties of different materials, it can be ensured that each component fulfills its intended purpose and withstands the demands of modern automotive applications.

We at Hashimoto Precision are ready to be the ideal choice for automotive manufacturers seeking cutting-edge stamped components that optimize material usage, exhibit superior stiffness and interchangeability, and promote lightweight design. Contact us today to get your needs met.

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Follow us

Copyright ? 2021 Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Mailbox